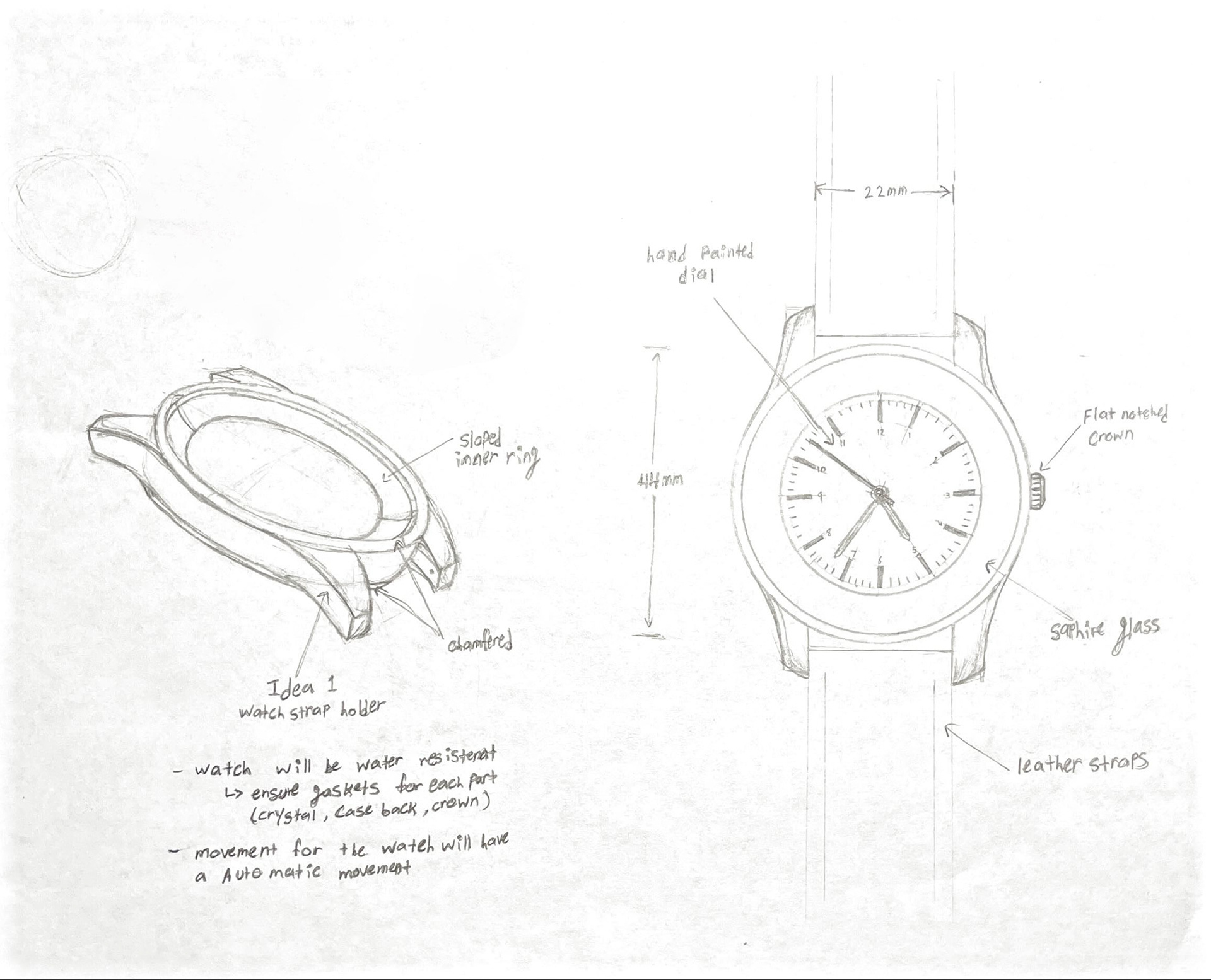

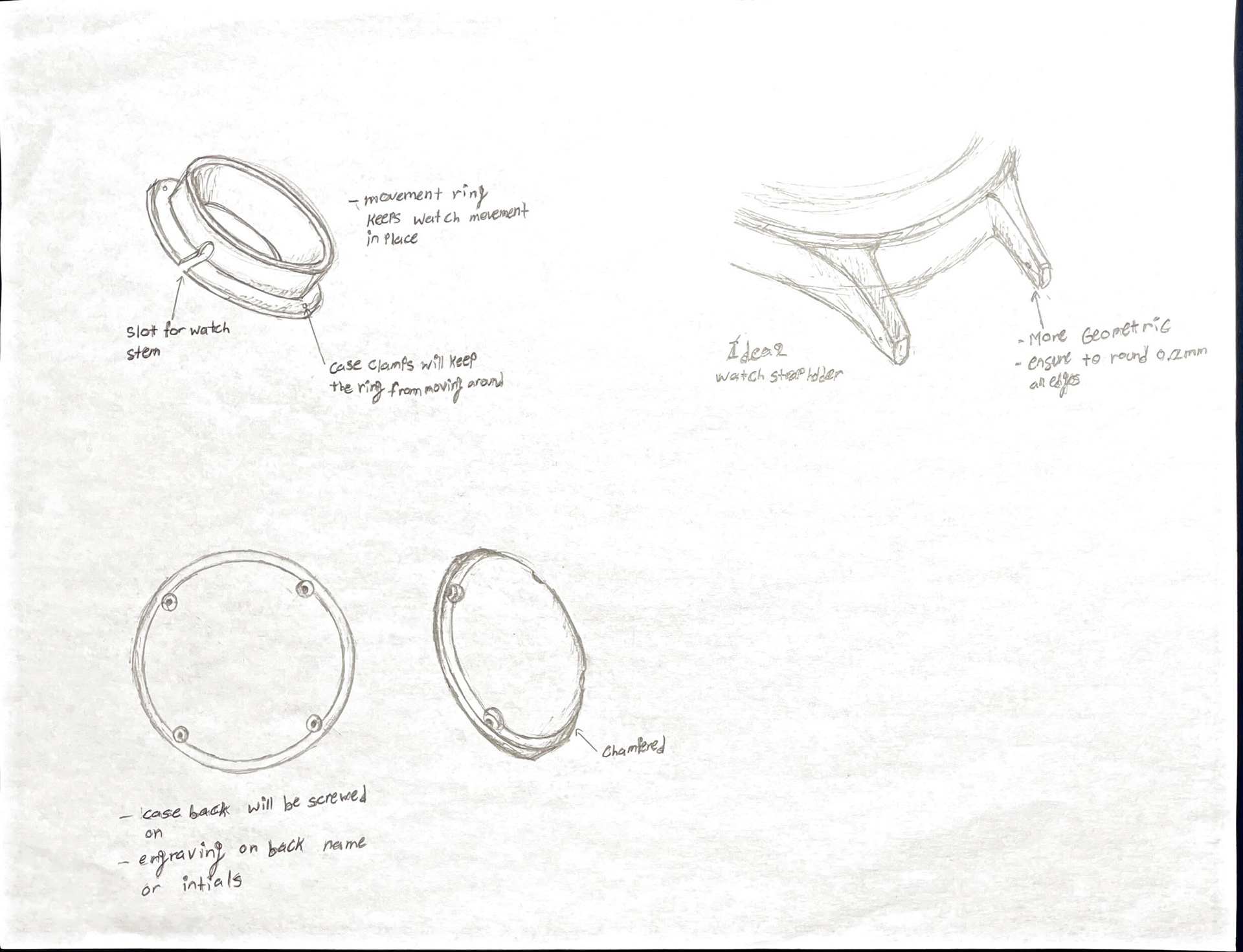

Concept Sketches

Initial quick sketches of components had been made with minor dimensions and aesthetics of the design.

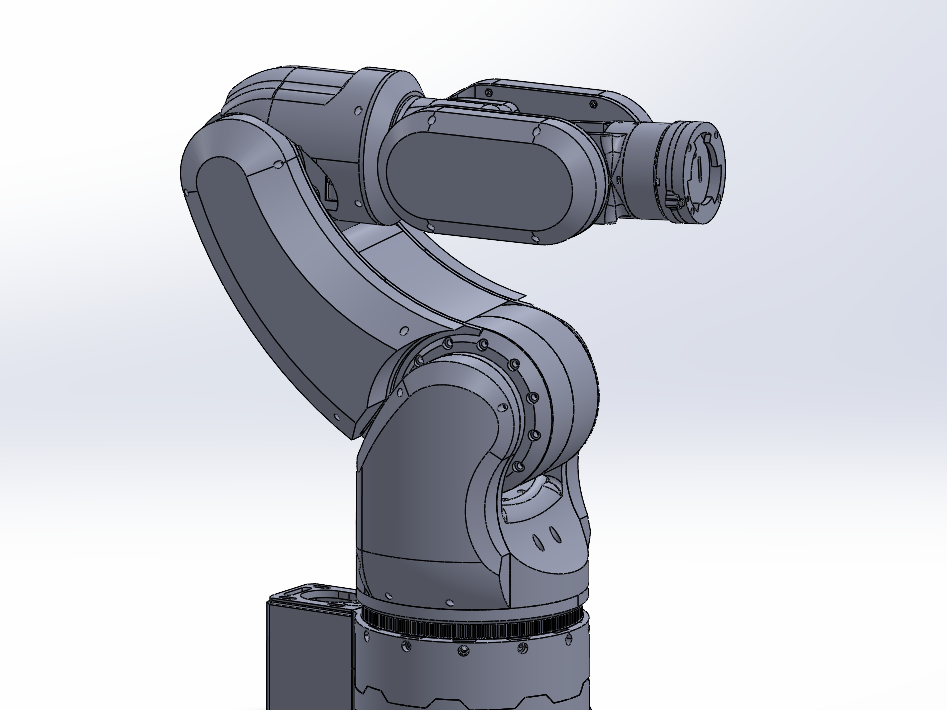

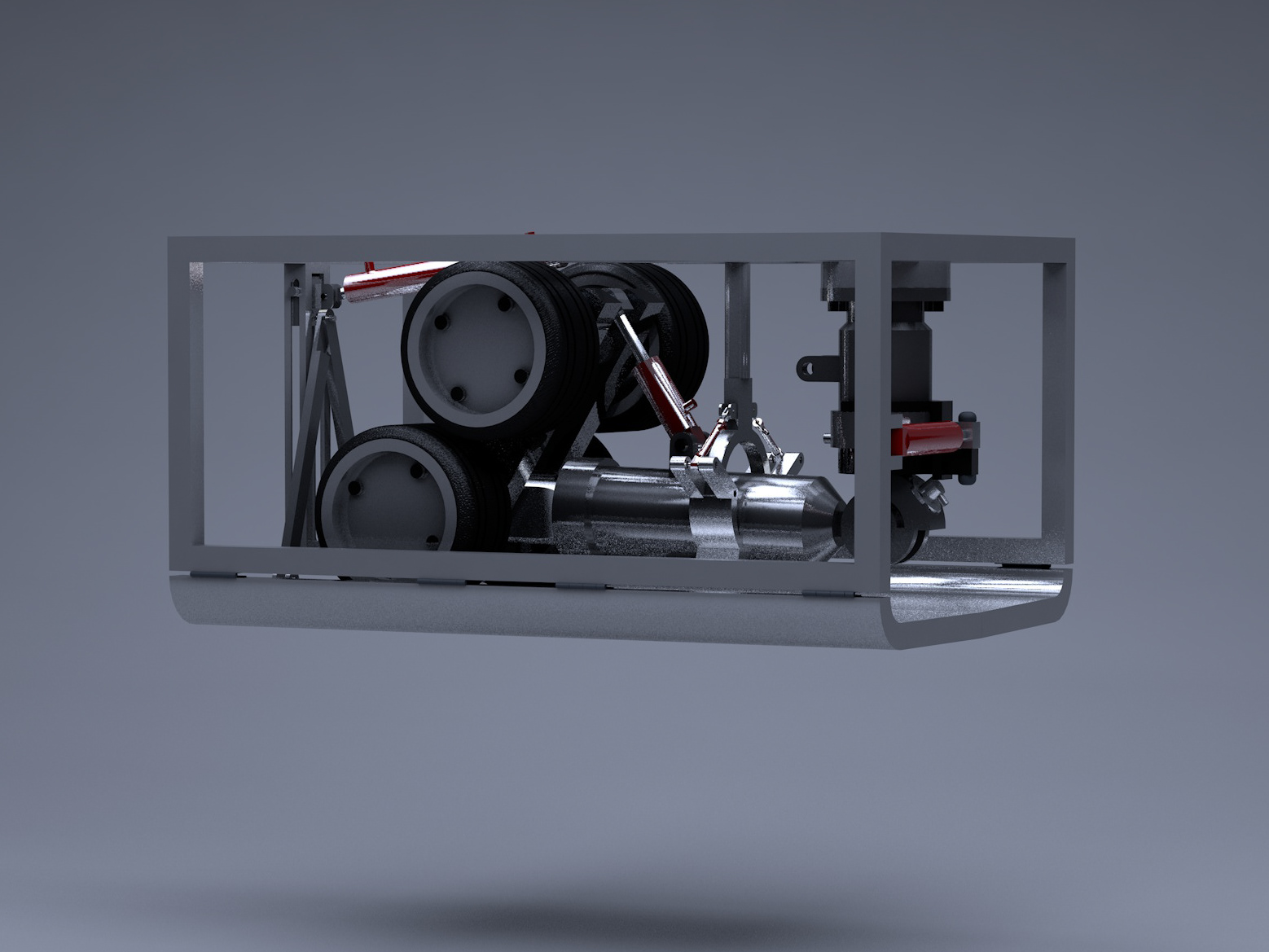

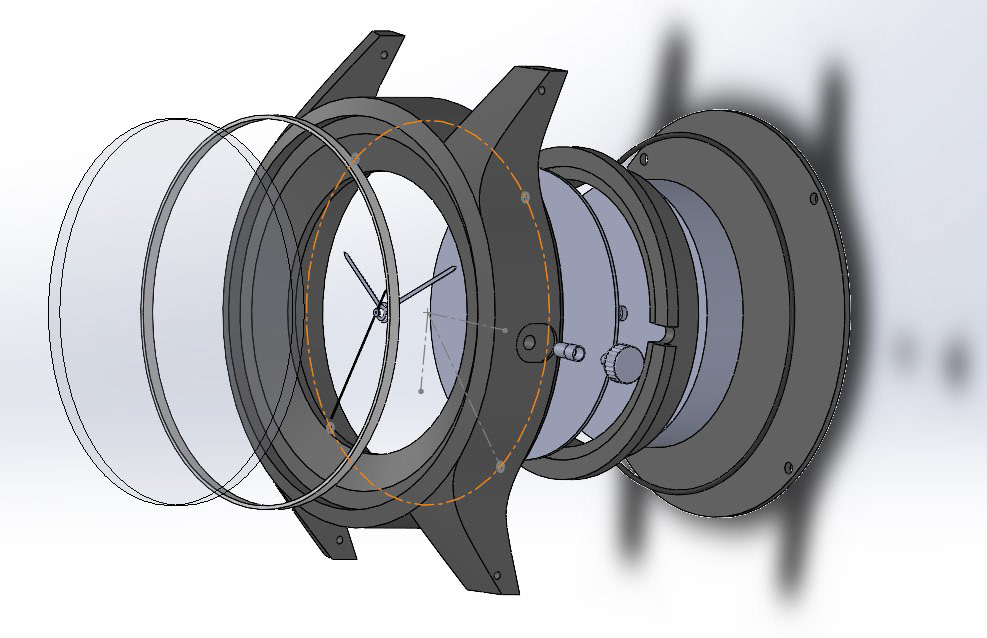

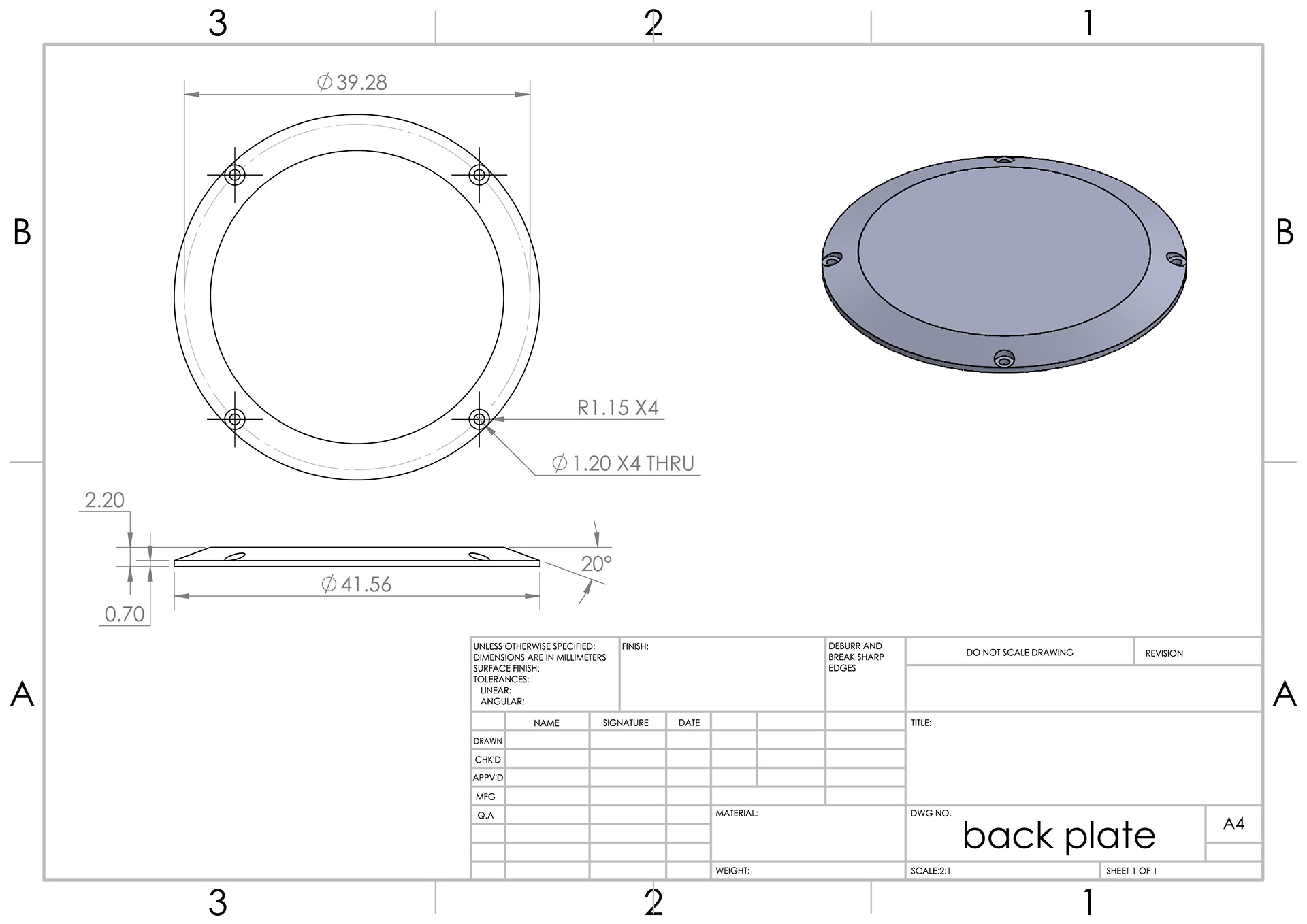

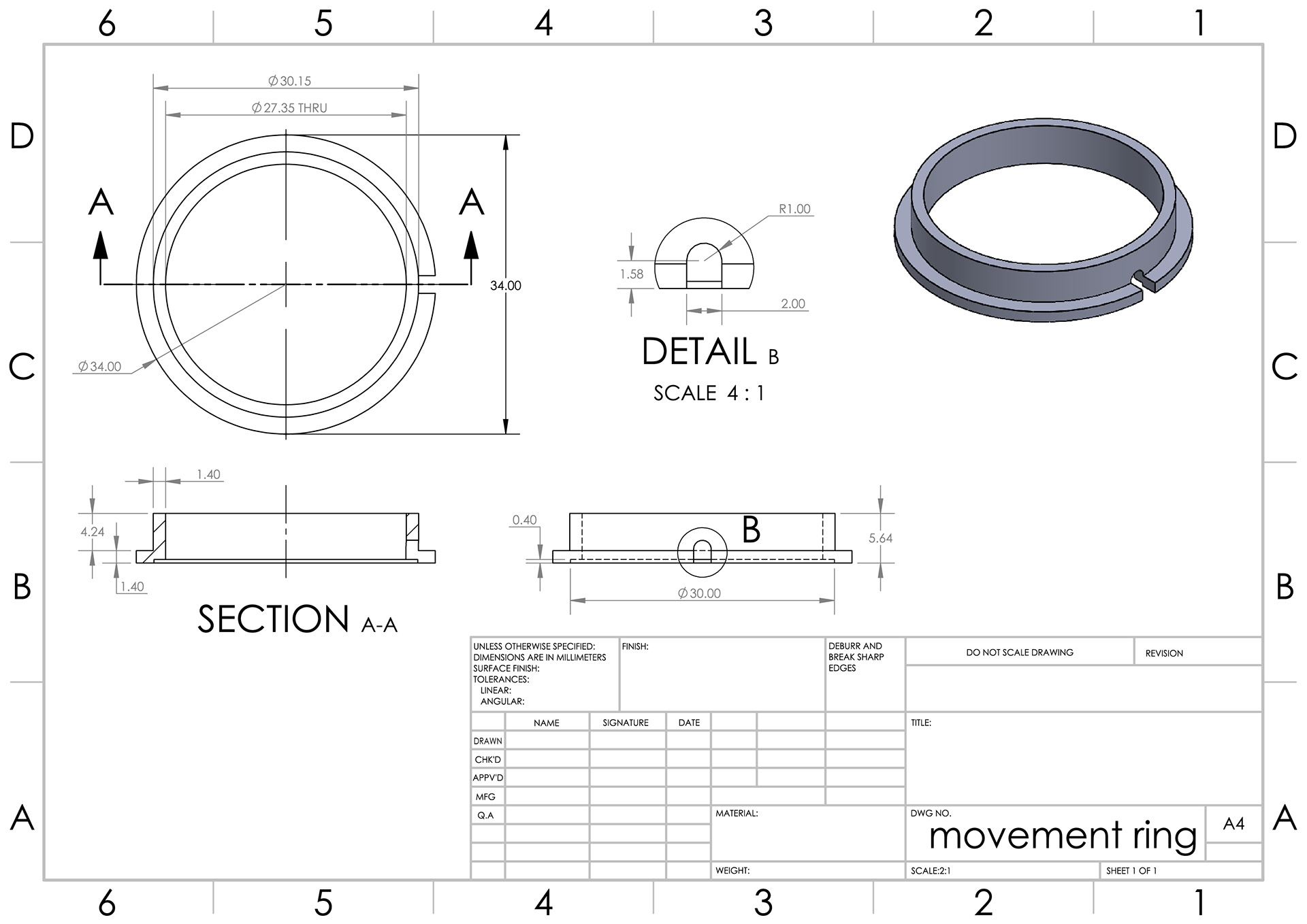

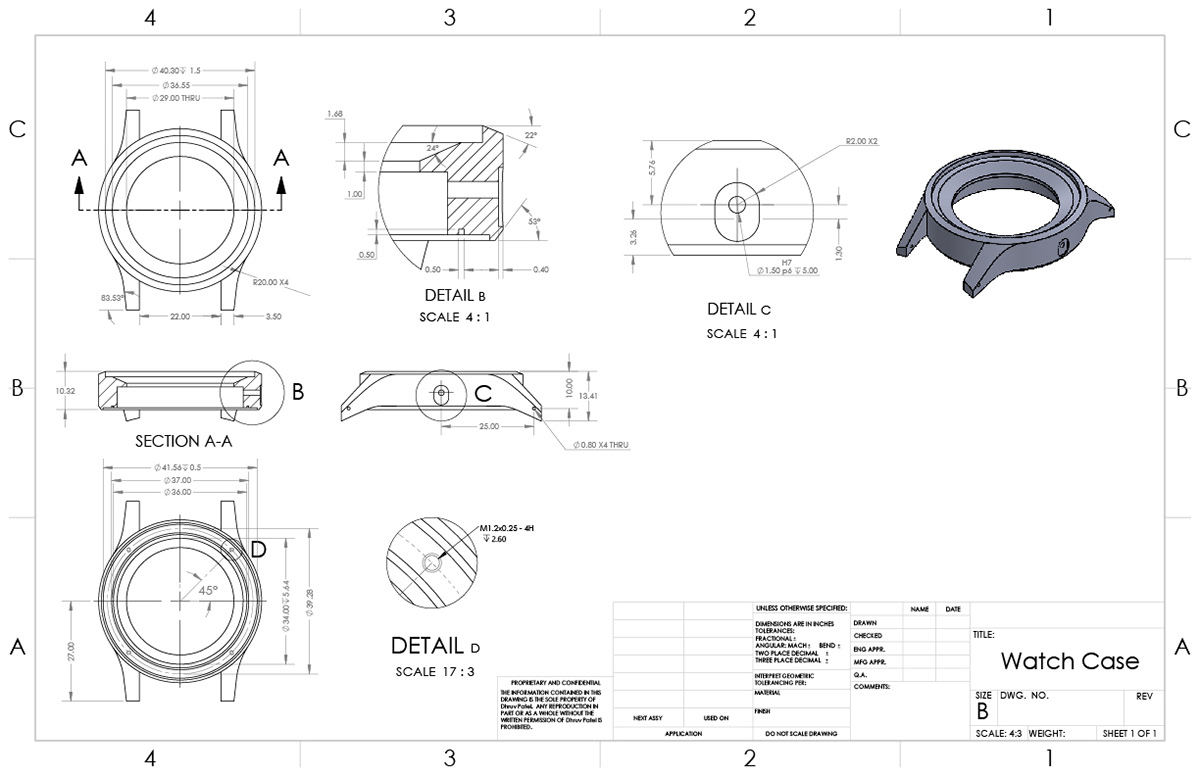

CAD

This is a CAD model of the watch with its internal components including the outer casing, movement ring, and case back. This watch is modeled based on a standard watch size of 44mm and from internal components to fit the form factor of the watch. Each and every component is designed from scratch and test fitted in SolidWorks.

Manufacturing Components

The parts were manufactured using 3D printing specifically an SLA printer from a service called 3d hubs. The resin type that was chosen was the Formlabs tough 2000 resin which was the ideal material for this project as it provided great mechanical properties like its Tensile strength of 46 MPa and tensile modulus of 2.2 GPa. Those properties will provide great strength but also allow for the crystal to be installed in the watch. Post-process work of sanding and painting was done to achieve the desired finish.

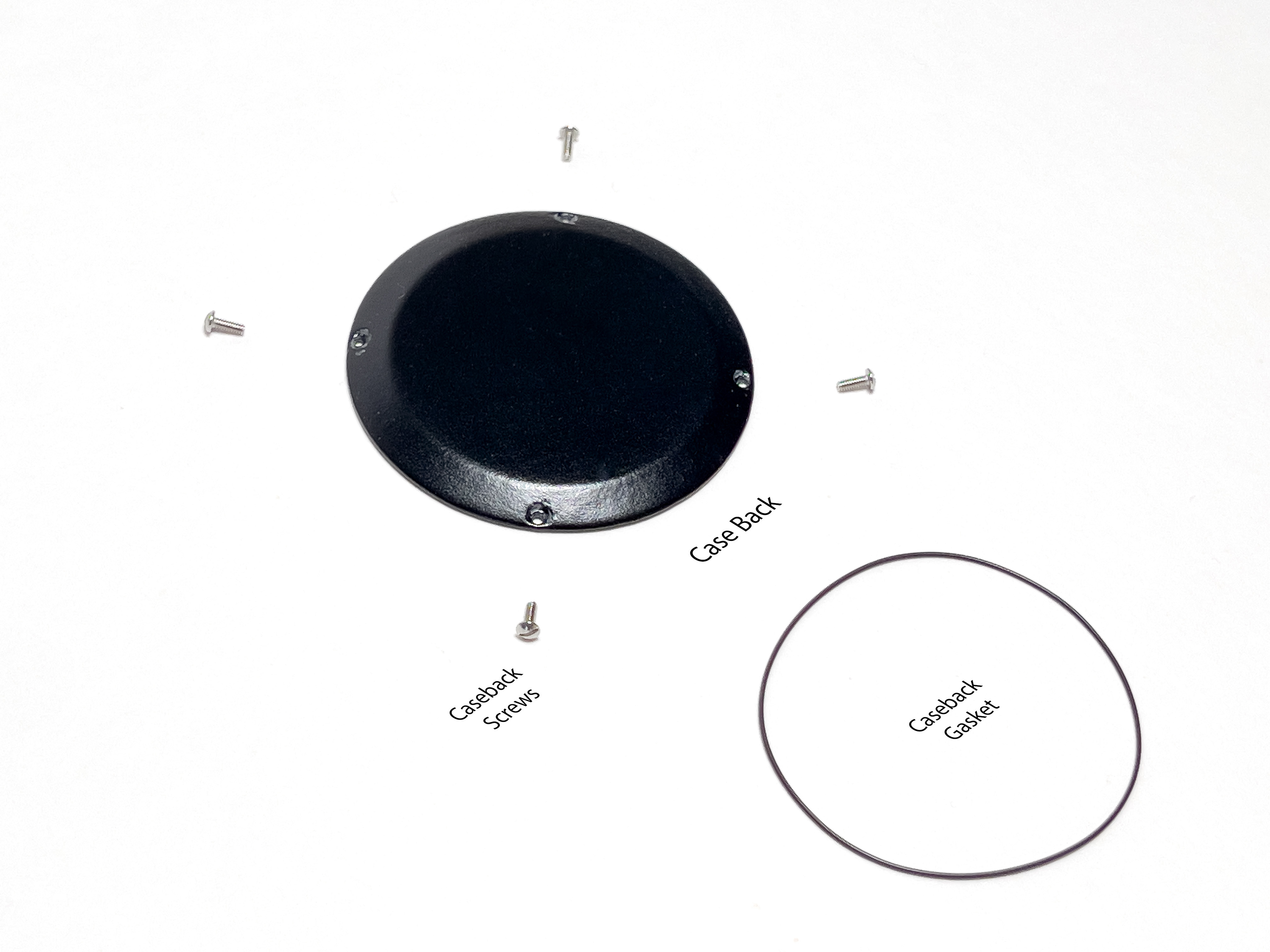

Watch Components

Final Product

All parts were assembled with the appropriate tools such as a crystal press, pin vise, and hand pressers.

This project ended in the successful completion of a working automatic watch that had tight tolerances allowing the parts to fit perfectly and allowing it to be water-resistant. Further knowledge was gained in manufacturing methods of producing parts with appropriate tolerances corresponded to it and understanding of mechanical properties of materials.